Survey and project studies are initiated by the Department of Survey, Design, and Environment after the inclusion of roads in the program by the Presidency of Strategy and Budget. The primary goal of highway projects is to design safe, sustainable, environmentally friendly, and cost-effective projects for all road users. This aim is crucial for establishing a reliable road network.

The first stage of the studies is to determine a route suitable for the class of road to be projected. During the route study, various criteria such as road class, geometric standards, costs, traffic volumes, geological conditions, landslide and drainage factors, social and natural constraints, etc., should be considered.

Once the route is determined according to the criteria, surveying studies along the route commence. Although various methods are used in survey studies due to the rapid advances in mapping technology, the photogrammetry method is mostly preferred due to its effectiveness and high accuracy.

The design phase is the most important part of highway project production. Project elements such as horizontal and vertical alignment, cross-sections, quantity and drainage studies, and intersections are meticulously designed using Computer-Aided Design (CAD) software by the staff.

During the survey and design studies, the road route and alternative routes are determined just before the process of Environmental Impact Assessment (EIA) of the road begins. Within the framework of the Environmental Impact Assessment (EIA) studies, the General Directorate of Highways examines the project description, the chosen project location, the economic and social dimensions of the project, the current environmental and socio-economic features of the affected area, the effects of the project on the area, and the precautions to be taken. The EIA report thoroughly evaluates the project's impact on the physical, biological, and socio-economic environment during the construction and operation phases, as well as the alternatives considered. The aim is to protect the historical and natural environment while assessing the project's effects on the socio-economic environment and making informed decisions based on these evaluations.

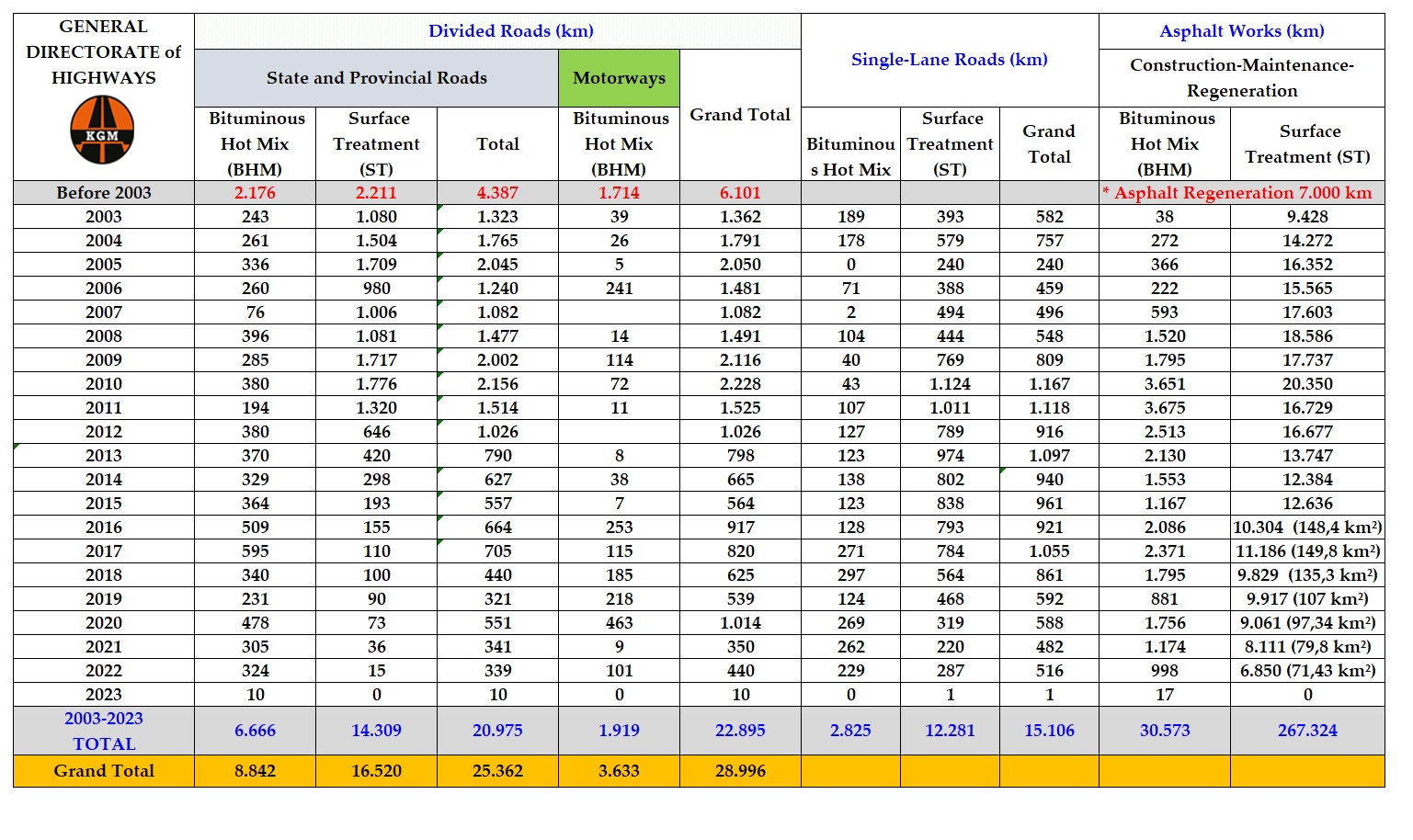

The Road Construction Department of the General Directorate of Highways has undergone significant transformations over the years. Initially focused on constructing accessible roads for year-round passage, the department now aims to create roads that are safe, comfortable, fast, uninterrupted, environmentally friendly, and contribute to improving the quality of life for society. These roads are designed to be an integral part of the transportation sector and sustainable in the long term.

With the continuous population growth, technological advancements, and increased vehicle usage for passenger and freight transportation, there is a need for more investment and upgrading existing road standards. Overcoming the challenging geographical conditions of the country requires the construction of high-standard, comfortable, and safe roads, often incorporating tunnels, viaducts, and bridged intersections.

In recent years, there has been a significant increase in the construction of divided roads, single roads, tunnels, and bridges/viaducts, showcasing the advancements in Türkiye's road transportation sector.

• Divided Roads: From 2003 to 2021, a total of 20,626 km of divided roads were constructed on national and provincial roads, increasing the overall length of divided roads to 25,065 km. Among this, 8,550 km is constructed using hot mix asphalt (HMA), and 16,515 km utilizes bituminous surface treatment.

• Single Roads: Between 2003 and 2021, 14,588 km of single roads were built, raising the total length of such roads to 14,608 km. Out of this, 2,606 km is constructed using hot mix asphalt (HMA), and 12,002 km utilizes bituminous surface treatment.

East-West Axles: Türkiye, situated at the crossroads of three ancient continents, holds a significant position in international road transport as an east-west corridor country. The East-West Highway Corridors, spanning a total length of 8,524 km, have played a crucial role in connecting different regions. Among these corridors, the 7,760 km long sections comprising 5 axles have been completed and opened to traffic, facilitating efficient transportation.

Currently, construction works are underway for the remaining 278 km, which is expected to be completed through a tender process. Additionally, preparations for the tender of the remaining 485 km of road are in progress, aiming to further enhance the connectivity and efficiency of the East-West Highway Corridors. These efforts signify Türkiye's commitment to developing and expanding its road infrastructure to support international transportation networks and strengthen its position as a key transit country.

|

East-West Axles | | | | |

|

Axle |

Total Lenght |

Completed |

Continuing |

Will be tendered |

|

D010-D020 |

1.552 |

1.249 |

70 |

233 |

|

D100 |

1.852 |

1.852 |

0 |

0 |

|

D200 |

1.235 |

1.235 |

0 |

0 |

|

D300 |

1.925 |

1.898 |

0 |

27 |

|

D400 |

1.960 |

1.527 |

208 |

225 |

|

TOTAL |

8.524

(100%) |

7.760 (91%) |

278 (3%) |

485 (6%) |

North-South Axles: The growth in trade, particularly the increase in foreign trade volume, imports, and exports, has highlighted the need for efficient and technically advanced utilization of our ports, as well as the establishment of effective highway transportation connections between these ports within our country. The Black Sea serves as a key route for trade with Caucasus and Central Asian countries, Russia, and Northwest European countries, while our Mediterranean ports facilitate trade with the Middle East, Africa, Southern Europe, and transoceanic countries.

To ensure seamless transportation of goods and cargo arriving at these ports to various centers within the country, it has become crucial to improve the north-south axes. A significant milestone has been achieved with the physical and geometric enhancement of 10,684 km out of a total of 12,146 km, encompassing 18 axes. These improved corridors provide vital connections with border gates, ports, railways, and airports, linking North Anatolian cities and Black Sea ports to our industrial centers and southern ports.

Continued efforts are underway to work on the remaining 778 km of the north-south corridors, with plans to tender for 683 km. These initiatives aim to strengthen the connectivity and infrastructure of our transportation network, enhancing trade flows and supporting economic development across various regions of the country.

|

North-South Axles | | | |

|

TOTAL |

DIVIDED ROAD |

SINGLE ROAD

|

| COMPLETED PARTIES |

10.684 (88%) |

9.850 (91%) |

834 (%62) |

|

CONTINUING PARTIES |

778 (5%) |

608 (6%) |

170 (%13) |

|

WILL BE TENDERED PARTIES |

683 (6%) |

354 (3%) |

329 (%25) |

|

FINAL TOTAL |

12.146 (% 100) |

10.813 (89%) |

1.333

(11% ) |

The General Directorate is actively involved in promoting cooperation and coordination for the procurement and utilization of foreign loans. Additionally, it takes the necessary steps to ensure traffic safety on construction sites by installing or arranging for the installation of traffic signs. Moreover, the Road Construction Department is responsible for overseeing the displacement of lines within the highway border line during the construction of highways, in accordance with protocols to be signed with relevant institutions and organizations.

Bala Bridge Interchange Pertek - Tunceli Road

Adıyaman Altınşehir Bridge Interchange Maçka – Karahava Road

Kalkan – Fethiye Road

MOTORWAYS

Türkiye's motorway network has experienced significant growth over the years. As of April 2022, the network has expanded from 1,714 km in 2003 to 3,633 km. These motorways play a crucial role in connecting major cities like Istanbul, Ankara, Izmir, Bursa, and Adana, as they are located on routes with high traffic volumes.

The current motorway network of 3,633 km facilitates transportation between Europe and Middle East countries, forming a significant portion of the Trans-European Motorway (TEM) within Türkiye's borders. These motorways contribute to the efficient movement of goods, services, and people, supporting regional and international connectivity.

The continuous expansion and development of the motorway network reflect Türkiye's commitment to enhancing its transportation infrastructure, fostering economic growth, and improving connectivity within the region.

As part of the road network that enables seamless transportation from the West to the East of Türkiye, serving as a bridge connecting Europe to the Caucasus, the Middle East, and Central Asia, 10 highway projects spanning a total length of 1,611 km were awarded through the Build-Operate-Transfer (BOT) model.

Among these projects, construction work for 1,351 km of roads has been successfully completed in 7 projects. The remaining 3 projects are still in progress, with construction work ongoing for a section covering 260 km.

These highway projects play a crucial role in enhancing connectivity and facilitating efficient transportation across Türkiye and its neighboring regions. By leveraging the BOT model, Türkiye aims to leverage private sector participation in infrastructure development, promoting economic growth and regional integration.

Here is a list of Motorway projects in Türkiye:

1. Istanbul-Bursa-Izmir Motorway (including Osmangazi Bridge): 426 km

2. Northern Marmara Motorway Odayeri - Kurtkoy Section (including Yavuz Sultan Selim Bridge): 148 km

3. Northern Marmara Motorway Kinali-Odayeri Section: 80 km

4. Northern Marmara Motorway Kurtkoy-Akyazi Section: 170 km

5. Menemen-Aliağa-Çandarlı Motorway: 96 km

6. Ankara-Niğde Motorway: 330 km

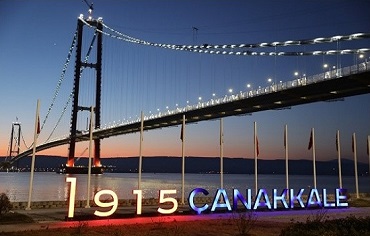

7. Kinali-Tekirdağ-Çanakkale-Balikesir Motorway Malkara-Çanakkale Section (including 1915 Çanakkale Bridge): 101 km

8. Aydin-Denizli Motorway: 163 km

9. Northern Marmara Motorway Nakkaş-Başakşehir Section: 45 km

10. Çeşmeli-Erdemli-Silifke-Taşucu Motorway (Çeşmeli-Kızkalesi Section): 52 km

NMM TEM GEBZE PORT INTERSECTION

THE IMPLEMENTATION OF INTELLIGENT TRANSPORTATION SYSTEMS

Non-Stop Tolling Systems on Motorways and Bosphorus Bridges (NTS)

To address the traffic problems caused by population growth and increasing vehicle ownership in Türkiye, the General Directorate of Highways has implemented a non-stop tolling system. This system aims to reduce time loss and facilitate fast transportation, particularly during peak hours in major cities. Currently, there are 103 Toll Collection Stations operating across the country, with 14 of them utilizing the Free Pass System. These toll stations help streamline the toll collection process and ensure smoother traffic flow on highways.

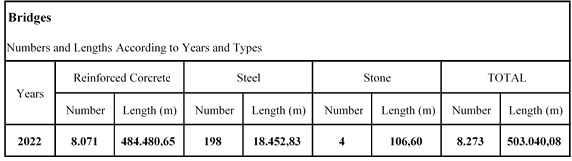

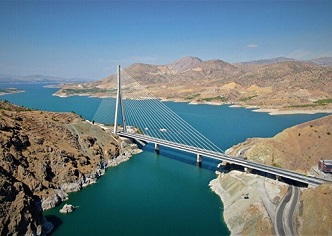

Bridges play a vital role in the highway infrastructure, and significant advancements have been made in their design and construction methods since the establishment of the General Directorate of Highways. In the past, bridges were primarily made of wood or stone, and they were narrow, had short spans, and low load capacities. However, in the Republican era, old bridges were replaced with reinforced concrete and steel structures.

With the establishment of the General Directorate of Highways, bridge construction gained momentum, and in recent years, the use of new technologies has allowed for the construction of prestressed reinforced concrete bridges. Advanced construction techniques are employed to build long and high bridges, particularly over large rivers, dam lakes, and deep valleys, using state-of-the-art technology.

The General Directorate of Highways is responsible for various aspects of bridge construction. This includes preparing projects and technical specifications, conducting land and hydraulic surveys, and designing the bridges or outsourcing the work through tender processes. Cost analysis is performed, and bridges are built according to the project, specifications, contract, and technical principles.

Throughout the construction process, the organization carries out necessary technical inspections, maintains work schedules, and oversees other essential procedures. The General Directorate of Highways is also involved in the maintenance and restoration of historical buildings, maintenance and repair of bridges, and providing opinions on special load passage permits for bridges. Additionally, it oversees the construction of temporary panel bridges in areas where old bridges are out of service, prepares project and study programs for new bridges, and maintains an inventory of existing bridges.

Nissibi Bridge on Ataturk Dam Reservoir Ağın Bridge on Keban Dam Reservoir

(Cable-Stayed Bridge on Adıyaman-Diyarbakır Road) (Cable-Stayed Bridge on Elazığ-Ağın Road)

Kömürhan Bridge on Karakaya Dam Reservoir

(Cable-Stayed Bridge with a single pylon on Malatya-Elazığ Road)

TUNNEL WORKS

Tunnels are underground passages created through excavation, and they serve various purposes such as railways, highways, pedestrian roads, and canals. They are used in situations where it is technically or economically impractical to have a surface-level transportation route. Tunnels have become increasingly necessary due to the growth in traffic volume on both land and sea, particularly in mountainous regions.

In Türkiye, tunnel construction projects are prioritized as part of extensive road development programs. The country focuses on tunnel projects to establish key transit corridors for international transportation networks, to provide access to geographically challenging high mountainous areas (with an average elevation of over 1100 meters), and to enhance traffic safety during harsh winter conditions.

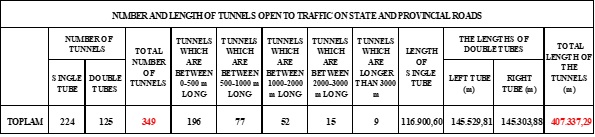

As of January 1, 2022, there are 349 tunnels with a combined length of 407 km on state and provincial roads in Türkiye. The maintenance, repair, and operation of these tunnels are carried out by 15 Tunnel Maintenance and Operation Chiefdoms, 38 Tunnel Control Centers, and 25 Branch Chiefs. These entities are responsible for ensuring the safe and efficient operation of the tunnels and implementing necessary maintenance and repair activities.

ROAD SAFETY WORKS

Rumble Strip Applications: Rumble Strip Applications: Rumble strips are utilized to enhance traffic safety by alerting drivers through sound and vibration when they become drowsy, fatigued, or unintentionally drift off the road. According to accident analysis data, run-off-road incidents are the leading cause of fatalities and injuries on the road network managed by the General Directorate of Highways. It is recognized that drowsy, fatigued, and careless driving significantly contributes to the occurrence of single-vehicle run-off-road accidents. Based on accident analysis findings, the installation of rumble strips has resulted in a 40% reduction in single-vehicle run-off-road accidents along road sections where they are implemented.

Black Spot Improvement: Black spots are defined as locations or road sections with a high frequency of traffic accidents. The primary objective in addressing these black spots is to effectively reduce and prevent traffic accidents, minimize the risk of accidents, and consequently alleviate the human suffering and economic losses caused by fatalities and injuries. Measures and improvements are implemented to enhance safety and mitigate the factors contributing to accidents in these identified areas.

Before After

Road Safety Inspection: Road Safety Inspection plays a crucial role in proactively addressing road safety concerns during the planning stage of road projects. By emphasizing road safety at an early stage, the aim is to identify potential risks and hazards and implement preventive or alternative measures before any traffic accidents occur. This proactive approach helps in preventing negative consequences and ensuring that road designs and infrastructure prioritize the safety of road users.

Horizontal and Vertical Marking: Horizontal and vertical marking works in Türkiye are conducted in accordance with the "Highway Traffic Marking Standards" manual, which has been revised to align with the UN and European Conventions. Extensive efforts have been made to ensure Türkiye's compliance with the 1968 Vienna Convention on Road Signs and Signals. All necessary studies and preparations have been successfully completed, and the Convention entered into force after being published in the Official Gazette dated February 24, 2022.

Guardrail Works: The "Guardrail Installation Manual" has been published in Türkiye, following the development of the National Roadside Constraint System model. The purpose of this manual is to enhance traffic safety and minimize the losses caused by run-off-road accidents. It incorporates elements aimed at increasing safety on roadsides and medians. As part of regular maintenance, approximately 2% of the guardrails in Türkiye's road network are replaced each year due to degradation. Furthermore, the installation of "Motorcycle-Friendly Protective Guardrails" is being carried out on selected road sections as required.

Intelligent Transportation Systems: Studies on Intelligent Transportation Systems (ITS) applications are underway in Türkiye, aiming to utilize developing technologies for more efficient utilization of highway infrastructure and to enhance the transportation experience for road users in terms of safety and comfort. The objective is to systematically expand the deployment of Intelligent Transportation Systems, establishing a system structure that is compatible across various systems, independent of manufacturers, and adhering to standards. This approach encompasses the latest innovations and is centrally managed through common protocols and standards.

To facilitate effective communication between intelligent transportation systems and other transportation modes, efforts to expand the fiber optic cable communication infrastructure are ongoing. This will enable seamless communication and integration between different components of the transportation system.

A total of 18 Intelligent Transportation Systems Centers will be established in Türkiye. These centers will be distributed across the Regional Directorates of the General Directorate of Highways (GDH), with one center being set up in each region. Additionally, a Main Intelligent Transportation Systems Center (MITSC) was established at the GDH Headquarter.

These centers will serve as hubs for managing and coordinating intelligent transportation systems in their respective regions. They will facilitate the collection, analysis, and dissemination of real-time traffic data, as well as the implementation of advanced technologies to enhance traffic management, road safety, and transportation efficiency. The MITSC, located at the GDH Headquarter, serves as the central coordinating body, overseeing the operation and integration of the regional centers.

Visual of MITSC

As part of the Intelligent Transportation Systems Pilot Projects, two specific projects are being implemented:

1. Intelligent Transportation Systems Pilot Project at Antalya 13th Regional Directorate of GDH:

This project focuses on implementing intelligent transportation systems in the Antalya region, under the supervision of the 13th Regional Directorate of the General Directorate of Highways. The goal is to introduce advanced technologies and systems to enhance traffic management, improve road safety, and optimize transportation efficiency in the region.

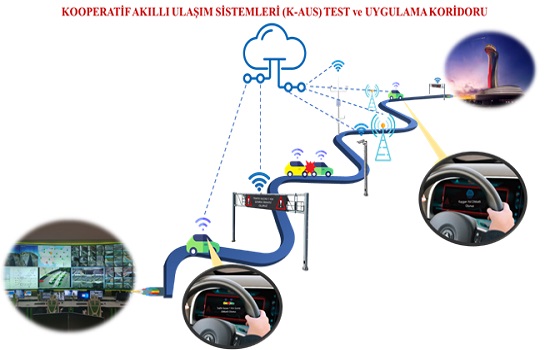

2. K-AUS Test and Application Corridor Pilot Project at Istanbul 1st Regional Directorate of GDH:

The K-AUS (Connected and Automated Vehicles, Urban Road Safety) Test and Application Corridor Pilot Project will be carried out in collaboration with the 1st Regional Directorate of the General Directorate of Highways in Istanbul. This project aims to establish a designated corridor for testing and implementing connected and automated vehicle technologies. It serves as a platform for testing various applications, evaluating their effectiveness, and assessing their impact on urban road safety.

The ITS Center Software-Platform and Mobile App, based at the Main ITS Center of the General Directorate of Highways, will develop the software infrastructure for all installed systems. It will enable centralized data collection, analysis, and control of various transportation systems, ensuring efficient traffic management and providing convenient access to information through the mobile app.

Transportation Safety: Highways play a crucial role in both freight and passenger transportation in Türkiye. They contribute significantly to the country's economic development and well-being. As a vital economic activity and service sector, road transport is closely interconnected with other sectors, exerting positive or negative influences on them. To ensure the longevity and effective operation of our roads, which have been upgraded through substantial investments, the General Directorate of Highways conducts inspections at 98 Highway Inspection Stations across the road network. These stations perform weight and size inspections in compliance with relevant laws and regulations. Additionally, inspections are carried out to monitor tachographs and working/rest periods, ensuring compliance with regulations.

The General Directorate of Highways grants "Special Permits" for empty vehicles and "Abnormal Load Transport Permits" for loaded vehicles that are involved in the transportation of indivisible abnormal loads with unique weight and dimension characteristics, which cannot be transported through other means of transportation. These permits allow for the safe and authorized movement of such loads on the road network.

Transportation Survey Studies: Transportation surveys are conducted to gather data and perform analyses that serve as the foundation for transportation planning. These surveys aim to contribute to the development of highways by providing a more rational and scientific approach to the design, construction, maintenance, and operation activities. The following studies are carried out within this framework:

- Traffic Flow Counts: These studies involve the use of both portable and fixed automatic counting and classification devices to collect data on traffic volume and vehicle types.

- Load and Weight Surveys: These surveys help identify the characteristics and trends of heavy vehicle traffic and freight transportation on highways. They provide valuable information for infrastructure planning and maintenance.

- Traffic Forecasts: Forecasting future traffic patterns is essential for feasibility studies and geometric and physical planning of road sections. Traffic forecasts assist in determining the anticipated demand and designing road infrastructure accordingly.

- Origin-Destination (O-D) Surveys: These surveys are conducted to estimate traffic flows and patterns for planned road construction projects. By analyzing the origins and destinations of travelers, transportation planners can make informed decisions regarding infrastructure development.

These studies enable transportation planners and engineers to make informed decisions, optimize resource allocation, and enhance the efficiency and safety of highway systems.Speed and Travel Time Surveys, Pedestrian Surveys, and Accident Analysis etc.

EQUIPMENT AND SUPPLY WORKS

The mechanized period for road construction started in 1948 in Türkiye. Before that time, roads had been constructed using human power. With the introduction of fast and modern techniques, the use of machinery became prevalent.

Prior to 1948, the General Directorate of Highways in Türkiye primarily relied on trucks and steam- or fuel oil-powered rollers for road construction. As the mechanized period began, the number of machines used in road construction increased. However, new challenges arose, including the need for qualified personnel to operate the machines, ensuring a steady supply of resources for their operation, maintenance and repair, and establishing workshops and personnel dedicated to machine procurement and specification drafting.

To address these challenges, technical units were established within the headquarters and divisions of the General Directorate of Highways. Training programs were implemented to educate personnel on machine operation, and efforts were made to expand the workforce responsible for managing the construction and maintenance equipment. As of January 1st, 2022, the General Directorate of Highways in Türkiye had 13,723 pieces of equipment with a total value of 679,553,051 US Dollars.

Considering annual programs and conducting inspections of the existing construction and maintenance equipment, necessary machines are provided while the current ones are maintained and operated as part of equipment and supply management. Workshops for repair and maintenance, as well as telecommunication infrastructure, are established. Additionally, required machines, accessories, and spare parts are either manufactured or procured by the General Directorate of Highways.

Our organization, played a pioneering role in mechanized works. In addition, we have successfully manufactured prototypes of machines that are required or intended for export, and we have initiated mass production for those machines that have been successfully produced in our country.

We have established comprehensive staff training programs that focus on the maintenance, operation, and repair of machines owned by the General Directorate of Highways. These training programs are regularly conducted to ensure that our personnel are equipped with the necessary skills and knowledge.

Furthermore, we have established a system to determine the maximum and minimum stock levels for each type of machine, vehicle, device, equipment, and spare parts. We also keep track of their annual consumption amounts, register them, and determine their operational costs. Based on these assessments, we ensure that the required machines, vehicles, devices, equipment, and spare parts are procured, stored, and delivered efficiently.